Global Fashion Forward: Exploring the Future of Clothing Production Services Worldwide is a rapidly evolving sector that is redefining how garments are designed, manufactured, and distributed across the globe. As the fashion industry continues to adapt to changing consumer demands, technological advancements, and environmental concerns, clothing production services are undergoing a transformation that promises to shape the future of fashion. This shift is not just about efficiency or cost savings; it’s about sustainability, innovation, and global collaboration. The integration of digital tools, automation, and eco-friendly practices is setting the stage for a new era in garment manufacturing.

The Rise of Digital Manufacturing

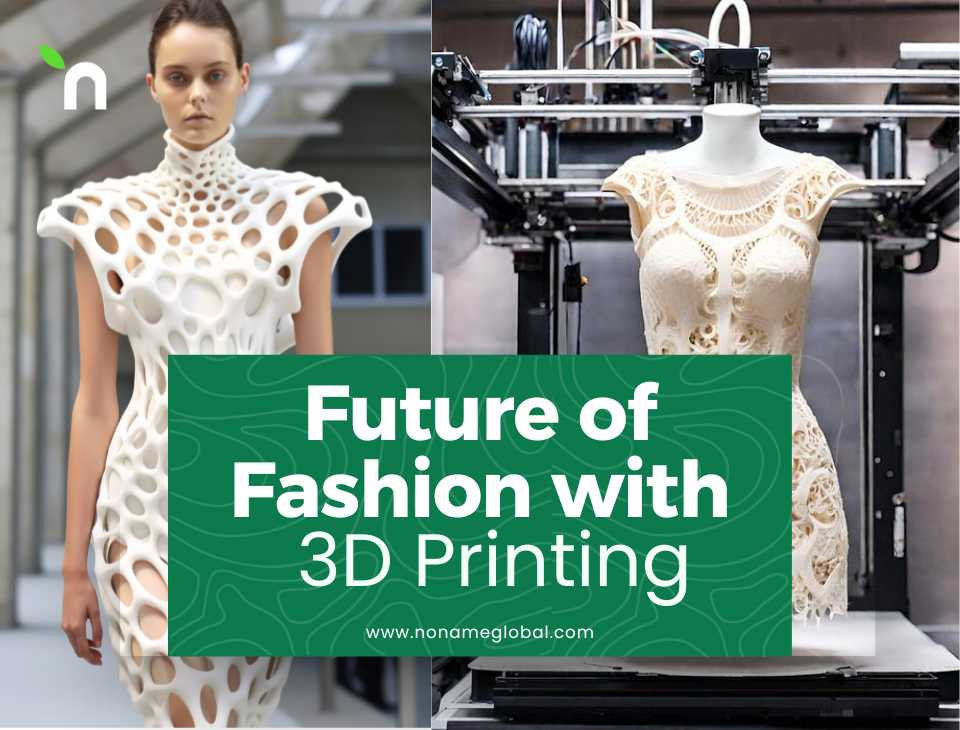

One of the most significant changes in the clothing production landscape is the adoption of digital manufacturing technologies. From 3D printing to computer-aided design (CAD), these innovations are streamlining the production process and reducing waste. For instance, 3D knitting machines can create entire garments in one piece, eliminating the need for cutting and sewing. This not only speeds up production but also minimizes fabric waste, which is a major concern in traditional manufacturing.

The use of AI and machine learning is also revolutionizing how brands predict trends and manage inventory. By analyzing vast amounts of data from social media, sales figures, and customer behavior, brands can make more informed decisions about what to produce and when. This data-driven approach ensures that clothing production is aligned with real-time demand, reducing overproduction and excess stock. As a result, brands can maintain a leaner supply chain while still meeting consumer expectations.

Sustainable Practices Take Center Stage

As consumers become more environmentally conscious, the pressure on clothing production services to adopt sustainable practices is intensifying. Brands are now prioritizing eco-friendly materials, such as organic cotton, recycled polyester, and biodegradable fabrics. These materials not only reduce the carbon footprint of garments but also appeal to a growing market segment that values ethical consumption.

In addition to material choices, sustainable production methods are gaining traction. Waterless dyeing techniques, energy-efficient factories, and closed-loop systems that recycle water and chemicals are becoming standard in many production facilities. These practices not only benefit the environment but also help brands meet regulatory requirements and consumer expectations. Moreover, transparency in the supply chain is becoming a key differentiator, with many companies publishing detailed reports on their environmental impact and labor practices.

Collaborative Models and On-Demand Manufacturing

Another trend reshaping the clothing production industry is the rise of collaborative models and on-demand manufacturing. Traditional mass production, which relies on large-scale orders and long lead times, is being challenged by more flexible approaches that allow for smaller batches and quicker turnaround. This shift is driven by the increasing demand for customization and personalization, as well as the desire for faster delivery times.

On-demand manufacturing, where garments are produced only after an order is placed, reduces the risk of overstocking and allows for greater flexibility in design and size options. This model is particularly beneficial for small and independent brands that may not have the resources to invest in large inventories. Furthermore, it enables brands to test new designs without the financial burden of producing large quantities upfront. The collaboration between designers, manufacturers, and retailers is also improving, thanks to digital platforms that facilitate communication and project management.

The Role of Automation and Robotics

Automation and robotics are playing an increasingly important role in clothing production, especially in regions with high labor costs. Tasks that were once performed manually, such as cutting, sewing, and quality control, are now being handled by machines. This not only increases efficiency but also improves consistency and reduces human error.

Robotic arms and automated sewing machines are capable of performing complex tasks with precision and speed, allowing manufacturers to scale production without compromising quality. In addition, these technologies help address labor shortages in some regions, ensuring that production can continue smoothly even in the face of workforce challenges. As automation becomes more advanced, it is likely to further transform the way clothing is made, making the process more efficient and cost-effective.

The Impact of Globalization

Globalization has always played a crucial role in the clothing production industry, but its influence is evolving in the modern era. While traditional manufacturing hubs like China and Bangladesh remain significant, new players are emerging in countries such as Vietnam, Ethiopia, and Cambodia. These nations are investing in infrastructure and training programs to attract foreign investment and build a competitive edge in the global market.

At the same time, the movement of production closer to end markets is gaining momentum. This trend, known as nearshoring, aims to reduce lead times and lower transportation costs by bringing manufacturing closer to consumers. It also helps brands respond more quickly to changing trends and customer preferences. However, nearshoring comes with its own set of challenges, including higher labor costs and the need for skilled workers.

Conclusion

The future of clothing production services is being shaped by a combination of technological innovation, sustainability efforts, and shifting consumer behaviors. As brands and manufacturers navigate this dynamic landscape, they must embrace change and find ways to balance efficiency, ethics, and creativity. The next decade will likely see even more disruption in the industry, with new technologies and business models continuing to redefine what it means to produce and consume fashion. For those willing to adapt and innovate, the opportunities are vast, and the potential for positive impact is significant.